Investigator: Jaewon Lee

Bearings are an important component of automobiles which directly affects the performance, life and fuel efficiency of the vehicle. Bearing manufacturers continues to reduce the size and thus to reduce the weight of the bearing. However, reduction in size leads to a smaller radius of each ball which results in a smaller contact zone and a higher contact pressure. Such adverse effects can reduce the life of the bearing by causing subsurface cracks and spalling failure of the raceway surface. The method developed is focused on reducing the computational time required to completely map the fatigue characteristics of the bearing and raceway. Since an automobile bearing experiences lateral, radial and vertical loading, a 3-D model of a bearing is inevitably required to obtain the contact pressure distribution on the raceway. Then, a single ball-raceway model approach is incorporated combined with the previously obtained contact pressure to calculate the multi-axial fatigue characteristics of the sub-surface of the bearing raceway.

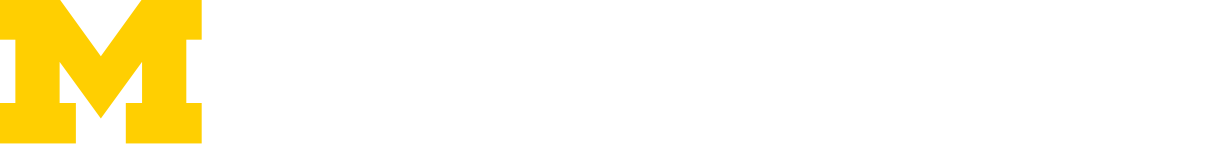

A 3-D bearing model is required to obtain the contact pressure distribution under a multi-axial loading environment.

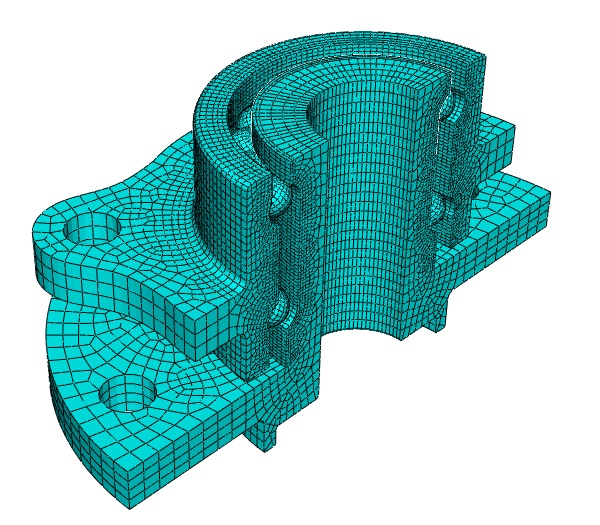

The subsurface stress distribution is required to understand the fatigue characteristics of the bearing raceway.