Investigation of Failure Mode and Fatigue Behavior of Flow Drill Screw Joints in Lap-Shear Specimens of Aluminum 6082-T6 Sheets

Seung Hoon Hong, Frank Yan, Shin-Jang Sung, Jwo Pan, Xuming Su (Ford) and Peter Friedman (Ford)

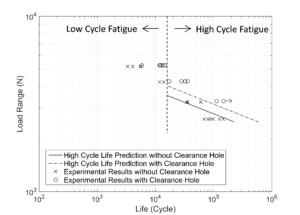

Failure mode and fatigue behavior of flow drill screw (FDS) joints in lap-shear specimens of aluminum 6082-T6 sheets with and without clearance hole are investigated based on experiments and a structural stress fatigue life estimation model. Lap-shear specimens with FDS joints were tested under cyclic loading conditions. The fatigue lives of the FDS joints in specimens with clearance hole are longer than those of the FDS joints in specimens without clearance hole for the given load ranges under cyclic loading conditions. A structural stress fatigue life estimation model is adopted to estimate the fatigue lives of the FDS joints in lap-shear specimens under high-cycle loading conditions. The closed-form structural stress solutions are based on the analytical solution for a plate with a rigid inclusion under a resultant shear load. The general trends of the fatigue life estimations are in agreement with those of the experimental results.

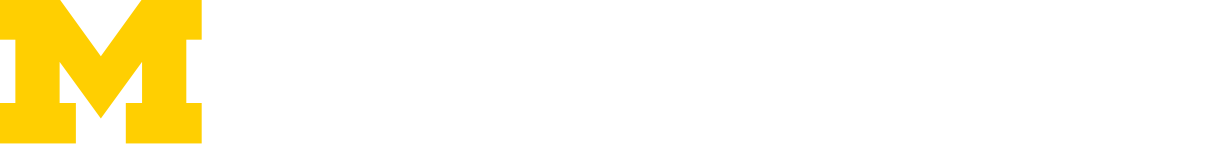

Figure 1. A micrograph of the cross section along the symmetry plane of a FDS joint in a lap-shear specimen with clearance hole.

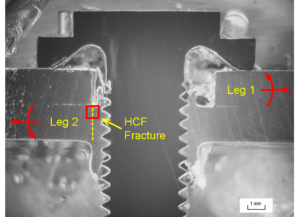

Figure 2. A micrograph of the cross section along the symmetry plane of a FDS joint in a lap-shear specimen without clearance hole.

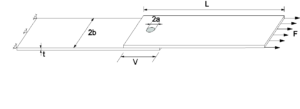

Figure 3. A lap-shear specimen with a FDS joint idealized as a rigid cylinder under the applied shear resultant force F.

Figure 4. Experimental results and the fatigue estimations based on the structural stress under high-cycle loading conditions.

- Hong, S. H., Yan, F., Sung, S., Pan, J., Su, X., and Friedman, P., 2016, “Investigation of Failure Mode and Fatigue Behavior of Flow Drill Screw Joints in Lap-Shear Specimens of Aluminum 6082-T6 Sheets,” SAE International Journal of Materials and Manufacturing, 9(3), pp. 2016-01–0501. DOI: 10.4271/2016-01-0501 (SAE 2016-01-0501)