Crack Tip Strain Distributions and Their Implications to Crack Growth Rate due to Stress Corrosion Cracking

Shin-Jang Sung, Nikhil Kotasthane, Yugo Ashida and Gary Was

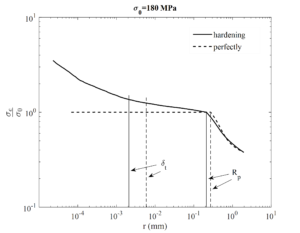

Stress and strain distributions near a crack tip in a round compact tension (RCT) specimen of elastic-plastic materials are studied by finite element analyses. The strain distributions are used to explore the use of the crack tip strain distributions for crack growth rate models due to stress corrosion cracking in unirradiated and irradiated steels with different yield stresses and hardening behaviors. Both power-law hardening and perfectly plastic materials are considered. The computational results indicate that the critical radial distance to the tip based on the crack tip opening displacement is outside of the Hutchinson-Rice-Rosengren (HRR) dominant zone for power-law hardening materials in a RCT specimen under the stress intensity factor typically considered for stress corrosion cracking. For both the power-law hardening and perfectly plastic materials, the computational results show that the strain distributions are different from those of the analytical solutions for the range of the radial distance larger than the critical radial distance based on the crack opening displacement within the plastic zones. The computational results suggest that for the stress intensity factor typically considered for stress corrosion crack growth rate models, computational results are needed to estimate the strain rate for developing crack growth rate models to correlate to the experimental data.

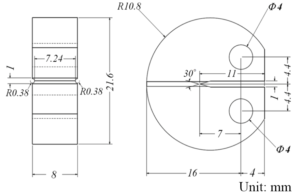

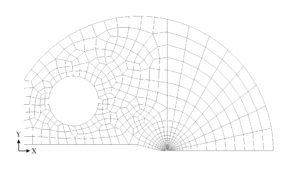

Figure 1. (a) A schematic of a round compact tension specimen with the dimensions expressed in mm, (b) a half two-dimensional finite element model for a round compact tension specimen.

(a)

(b)

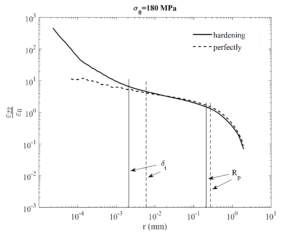

Figure 2. (a) The normalized Mises stress σe/σ0, and (b) the normalized opening strain ε22/ε0 directly ahead of the tip as functions of the radial distance to the tip for the power-law hardening and perfectly plastic materials with the yield stress σ0=180 MPa. ( δt: crack tip opening displacement; Rp: plastic zone size).

- S.-J. Sung, N. Kotasthane, Y. Ashida and J. Pan, 2015, “Crack Tip Strain Distributions and Their Implications to Crack Growth Rate due to Stress Corrosion Cracking,” ASME PVP Conference, PVP2015-45820, Boston, Massachusetts, July 19-23. DOI: 10.1115/PVP2015-45820. (PVP2015-45820)